Quality Control

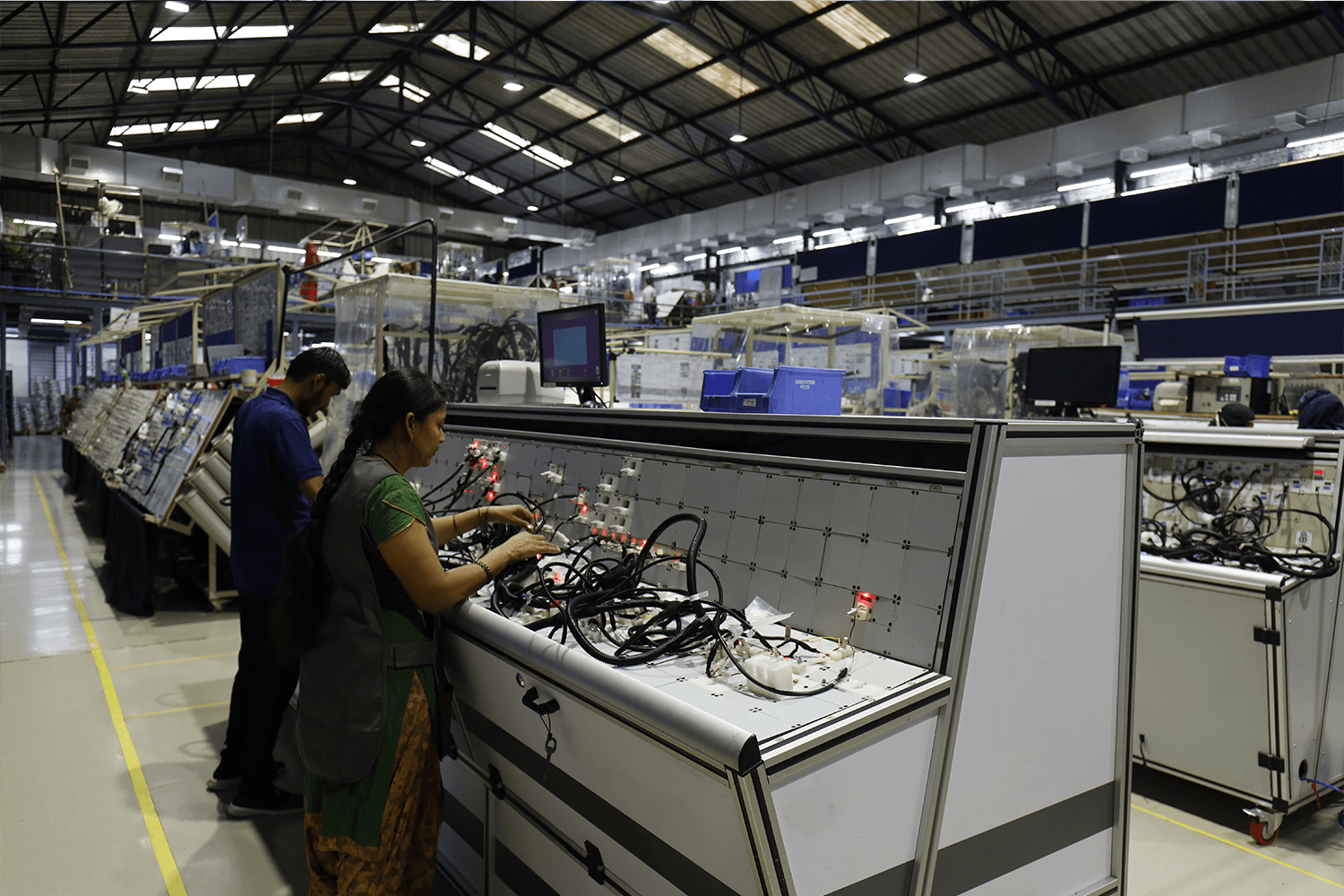

Latest technology and infrastructure enable harnex Systems to deliver cost-effective customer specific products with optimum quality. With focus on zero-defect, robust systems and processes, we are able to delight our Customers with best quality products. Highly advanced machinery and trained operators enable us to achieve better quality and performance resulting into higher production output and efficiency.

Our experience in processing of Critical harnesses have helped us earn a reputation in our Customers. We are prepared to take on challenges, and growing global demands of our Customers.

Quality Assurance Infrastructure

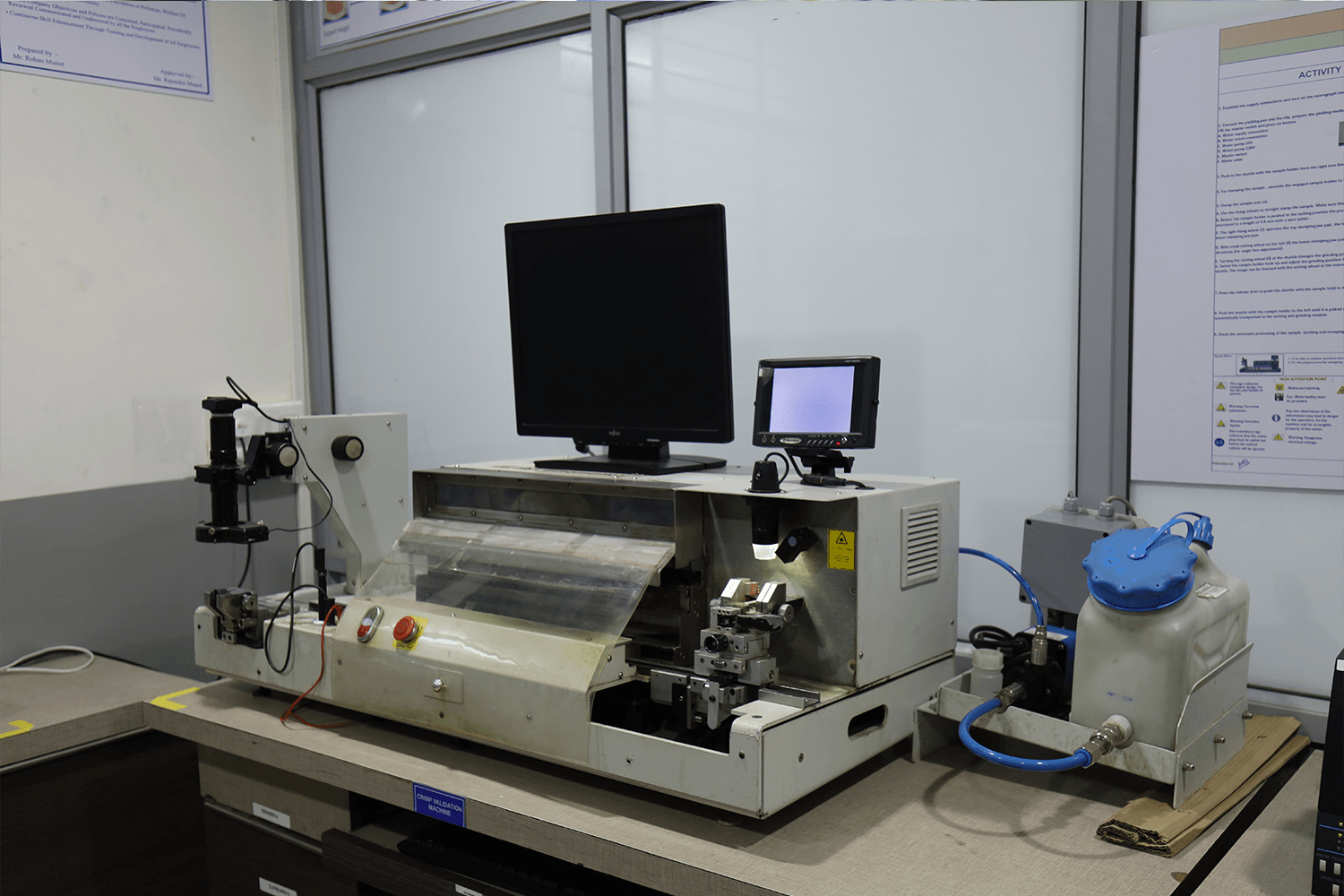

- SLE cross section analysis Lab for wire cross section upto 80 sq.mm

- SLE pull force testers for upto 500 kgs pull load testing

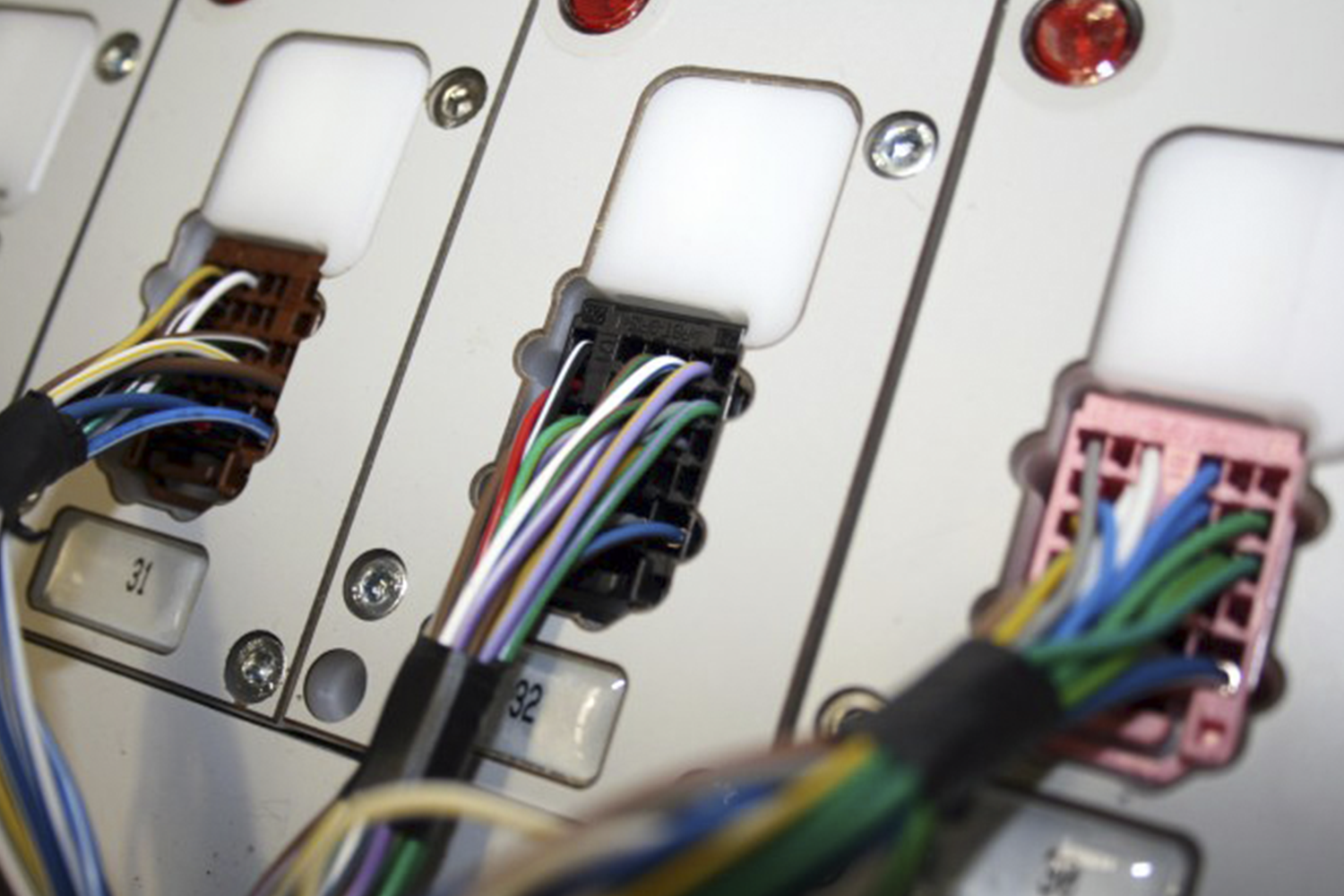

Advanced Crimp force Analyzers on Komax machines

- Integrated crimp height measurement devices K341

- Advance seal insertion units with seal position monitoring

- Crimp force monitors installed for all semi-automatic crimping machines

- TSK, Emdep testers for end of line circuit testing

- Clip checker, air leakage testing, pneumatic advanced test modules

- Vision based Emdep test table for fuse box checking

Certifications

Harnex Systems is Certified for QMS IATF-16949, ISO 9001, EMS ISO 14001 and OHS&S ISO 45001. We are committed to delivering global quality products when it comes to providing its customers on-time and to-specifications.

Training Infrastructure

- Well-equipped training facility for On-the-Job and Off-the-job training needs

- Training courses designed for ease of understanding

- Training games for interactive learning

- Advanced Training evaluation techniques