The Best Of Technology

The latest in technology and infrastructure enable Harnex Systems to deliver cost-effective customer-specific products with optimum quality. With a focus on zero-defect, robust systems and processes, we are able to delight our customers with the best quality products. Highly advanced machinery and trained operators enable us to achieve better quality and performance resulting in higher production output and efficiency.

Our experience in processing critical harnesses has helped us earn a reputation among our Customers. We are prepared to take on challenges, and the growing global demands of our Customers.

Engineering Technology

- Dedicated Engineering and R&D team of highly experienced engineers

- Our engineers are trained for working on various wiring harness design softwares like Arcadia Electrical, Siemens-Mentor Graphics Capital Harness XC and Capital Formboard XC

- Development of injection molded components and assemblies

- Proto Lab with expertise in fast and accurate development of wiring harnesses

- Experience of working with customers on various value addition – value engineering proposals which result in significant cost savings for our customers

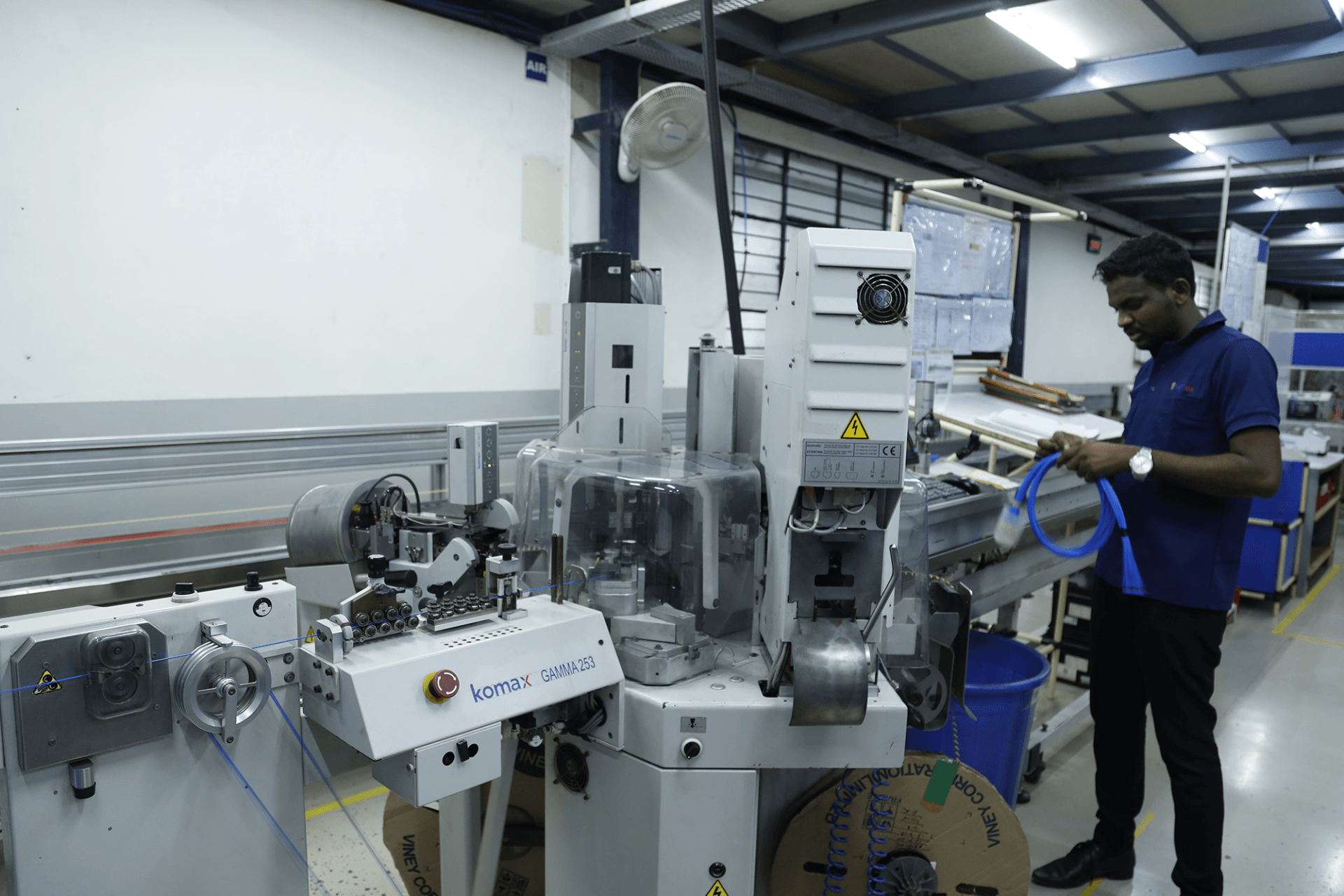

Manufacturing Technology

- Fully automatic cut-strip machines with both side crimp and seal insertion from world class manufacturers like Komax, Kodera and Schleuniger

- 12 mtr. wire twisting machines for EMI/EMC applications

- Schunk ultrasonic welding machines

- Integrated wire printing machines

- Tyco Raychem heat shrinking machines

- High end braiding machine for harnesses for rugged applications